The PRO Steel® PSDM-Manual-Serie - Swing Arm Series

Suitable for processing: Stainless steel • Aluminium • Steel • High tensile Steel

The PRO Steel® PSDM-Manual-Serie is a manually operating machine with which you can simply and quickly mill/grind various radii or bevels under various angels. With the PRO Steel® PSDM-Manual-Serie you apply cost-effectively and with little effort a proper bevel or mill/grind a radius (for example to ensure an adequate coating of the edges with powder coating). This way you can produce in accordance with all the applicable guidelines.

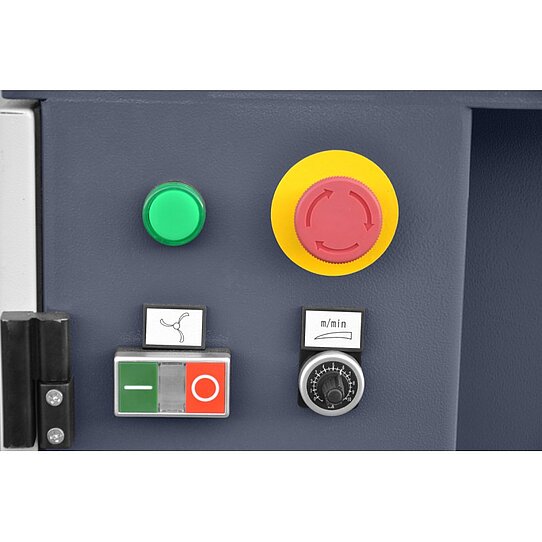

The PRO Steel® PSDM-Manual-Serie features a freely adjustable speed and a vacuum clamping table with a hole pattern. You can securely clamp workpieces on the table, in combination with the 2-button control you are always working in a safe manner.

By means of the balance arm and sufficient mass of the milling/grinding head you can, with little physical effort and vibration-free, mill a constant and accurate radius or slanted edge. The grinding head can be configured on various positions (angles) for diverse processes. Furthermore, the milling head features an intake, with which tools can be easily exchanged. Most of the available milling heads worldwide can be used on the PRO Steel® PSDM-Manual-Serie. Moreover, various adapters are available. The dimensions of the work surface are 1200 x 700 mm. This sets the maximum dimensions for a workpiece at 1000x800mm mm. There is no maximum length because the sides of the table can be easily lowered.

Polyvalent and flexible Swing Arm Grinding and deburring Machine

Deburring and edge rounding unit for small and medium sized production runs.

Swing Grinder

PSDM-Manual : PRO Steel® Manual - Serie

For economical deburring laser-cut or punched metal parts,The Profimach PRO Steel® PSDM Manual SwingGrinder bridges the gap between either manually labour using power tools or the more expensive through feed Machines and offers the semi-automatic solution.

The grinding head consists of two rotating disc tools mounted to a swinging arm equipped with a weight compensation device. This grinding head is guided over the workpiece by hand and grinding pressure is applied manually from above. The inside and outside edges of the workpiece are processed efficiently from all angles and directions. The grinding head can be tilted 180° , thus allowing for speedy switching from a deburring disc to a rounding disc for example.

- three to four times faster than manual deburring

- Easy-to-use with swinging arm and weight compensation

- High friction table cover, dust drawer and extraction outlet

- Rotatable head with deburring and edge rounding tools

- Numerous safety features including automatic motor shutdown when head is tilted and pneumatic brakes for swinging arm

- For laser-cut, plasma-cut and punched parts

- Processing of foil-covered or zinc-plated parts

- Processing of steel, stainless steel and aluminium

Flexibility is our first concern

Polyvalent Swing Arm Grinding and deburring Machine

Flexible swing arm deburring and edge rounding machine with vacuum working table

Manual-semi-auto sheet and plate deburring machine

Standard version:

– Movable arm in 2 positions with weight compensation.

– Deburring disc for the removal of rough burrs.

- Disc with a brush (installed in the machine)

- Disc with a non-woven abrasive

- A set of round discs made of sandpaper of different various gradation

– High friction mat for small parts.

– The grinding dust is collected in a removable tray.

– Frequency-controlled drive.

– 1 workbench.

– Weight approx. 270 kg.

– 400 V connection with vacuum table.

– 1.5 kW main motor.

– Side panels that can be adjusted with regard to height for personal protection and machining large parts.

– CE certified.

| Table dimensions | 1200×700 mm |

Maximum part dimension (inside the working table) | 1000x800mm |

| Swing Arm range | 1500mm ×360° |

| Vacuum operating area | 330×300 mm |

| Machine power | 1,5/0.75 kW |

Part thickness range | 1-150mm |

Dust extraction capacity required | 1000m³/ h |

| Total power | 4.5 kW |

| Power supply | 360/400V |

| Weight | 440 kg |

| Dimensions | 1705×995×1650 mm |

Versatile starter model and the cost saving alternative for manual deburring, edge rounding and/or finishing of metal.

The Manual Grinder for perfect deburring, edge rounding and finishing of metal. Portable head of the machine is equipped with two mounting handles, allowing for installing two types of grinding brushes. This ensures that an abrasive medium can be used for heavy-duty grinding on one side and, on the other side, for example, a brush for deburring, edge rounding and/or finishing. A mirror finish can also be created if required. Last but not least, the 180 degree rotating shaft makes rapid switching between different consumables easy.

The Manual Grinder is ergonomically responsibly designed for optimal operating conditions. The machine has a special mat with high friction surface to fix the parts during deburring and finishing. Smaller parts are kept fixed in their place through the integrated vacuum.

This machine is suitable for small batch parts deburring and edge rounding. It has much better working efficiency, and more consistent performance than traditional hand held angle grinder or orbital sander.

The arm allows for adjusting the clamping force exerted on the material according to the needs. Using a deburring machine is way more convenient than manual deburring.

ERGONOMIC DESIGN

This deburring machine is by default equipped with adjustable rotary speed.

A vacuum system ensures solid workpiece mounting, providing safety while operating.

This Machine is suitable for small batch parts deburring and edge rounding. It has much better working efficiency, and more consistent performance than traditional hand held angle grinder or orbital sander. It does a fantastic job on deburring and edge rounding of laser cutting, punching, stamping, and some flat machined parts.

This machine utilizes air spring support zero gravity swing arm design. The operator simply needs to grab the handles on the working head, and apply certain pressure on the part to start deburring and edge rounding freely.

The working table also has a partial vacuum area for accommodating small parts. Simply position the parts on the vacuum area, then the strong downdraft force will firmly hold the parts in place. Vacuum system included.

This deburring machine is equipped with dual abrasive disk and brush configuration which were driven by the same motor. Fast switching between the disk and brush, simply turn 180°, and then lock it. Patented design of quick consumable change of the abrasive disk and brush.

It is also capable of processing oversize parts (larger than the working table), as long as it is within the swing arm span.

A versatile machine with a rotatable head to swap between heavy grinding and edge rounding/deburring. Ideal for metalwork projects that require both deburring and grinding.

Long service-life flap brushes and therefore a reduction in material costs.

3 – 4 times faster than manual deburring.

Uniform edge rounding/deburring.

Affordable starting model.

Optimum user friendliness.

Dust Extraction Unit

Profimach offers a range of dust extraction units for removing harmful abrasive dust. Depending on the application they are available for wet or dry processing.

Vacuum Device included

For holding down smaller and lighter workpieces. For most applications the vacuum device is often required , especially for smaller parts..

Magnetic table for Small parts

For holding down smaller and tiny workpieces.

For most applications the vacuum device is often sufficient, but especially for smaller parts who are too small to create a vacuum under we offer an fully integrated magnetic table.

Full Vacuum Table

We can also deliver the machine with a full vacuum table over the whole surface with an extra high debit vacuum pump!

Optional build in Magnetic table

When vacuum is not enough for very small parts we can use the magnetic table

Optional brushes and Discs

We have the perfect solution for every job

our machine replaces all following: Profimach PSDM-Manual , PRO Steel® Manual – Serie, PSDM-Manual, Time savers The 10 series, Timesavers 10-Series 1300MG, Loewer Swinggrinder, GeCam Easy T, Q-fin Easy T, Q-fin Progrinder, Q-fin Top edge, swing grinder, deburring manual machine